India has finalized two ‘codes of safety’ for acetone and acetaldehyde, detailing properties of the two chemicals, hazards associated with it and proposing standard safety measures to control such hazards.

Drafted by the Bureau of Indian Standards, the codes of safety have been put out for public consultation and open for submission of comments till August 15, 2022 in case of acetone and till August 21, 2022 for acetaldehyde.

Once approved on completion of the consultation process the standards are intended to be a ‘guide’ for industry in recognizing the hazards and establishing safe handling procedures and standard operating procedures (SOP) in case of accidents.

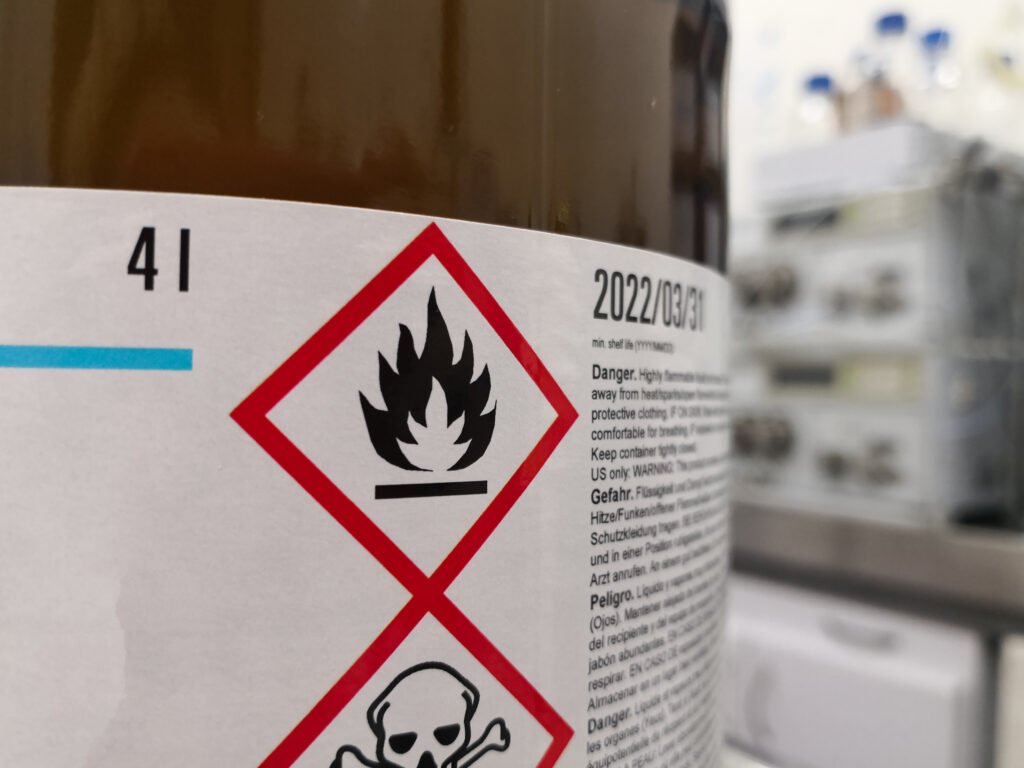

“Because of high flammability factors, a complete knowledge and understanding of the hazards involved are essential pre-requisites of handling acetone and acetaldehyde. The elimination of accidents is vital in public interest as accidents produce social and economic loss,” BIS notes in the draft introduction.

Towards this end, for the first time the codes details hazards to human through skin, ingestion, eyes, inhalation leading to risks of severe intoxication including ataxia, sedation, and coma, respiratory depression, gastrointestinal disorders (vomiting and hematemesis), hyperglycemia and ketonemia, acidosis and hepatic and renal damage may also occur.

Hence the code proposes standards for storage, handling, packing, labelling, and disposal of waste, cleaning and repairing of containers, selection and training of personnel, personal protective equipment, and first-aid.

It lays down specific toxicity values of each of the chemicals classifying short term exposure, immediate danger to life and health, median lethal dose, lowest published lethal dose and inhalation rate.

The code specifies personal protection equipment under categories of eye/face protection, skin protection, non-respiratory equipment, foot and leg protection, body skin protection,

On storage, handling, labelling and transport the standards proposed are:

Acetone: https://www.services.bis.gov.in/tmp/WCCHD34619871_16062022_1.pdf

Storage

- Storage tanks may be constructed of stainless steel. The storage tanks should be placed in retaining basins, also to be constructed of concrete or welded steel.

- Pipelines shall be supported by steel stanchions or concrete sleepers. Wood shall not be used. Pipelines shall have adequate electrical continuity and shall be earthed.

Handling

- Pipelines shall be supported by steel stanchions or concrete sleepers. Wood shall not be used. Pipelines shall have adequate electrical continuity and shall be earthed.

- As Acetone is a solvent, the selection of compatible material must prevent the material itself being dissolved. Acetone is a polar solvent and must not be combined with similar materials such as PVC, natural rubber as these elastomers will inherently fail. Compatible materials include most metals, polytetrafluoroethylene (PTFE) and tetrafluoroethylene (ETFE).

- One storage tank equal in capacity to the largest tank in use should be kept free at all times to transfer acetone in case of emergency.

Labelling

- Each container including tankers should carry an identifying label or stencil as depicted in Indian Standards (IS) 1260 (Part 1). The storage containers shall be labelled or marked to identify with contents of the container, name and address of the manufacturer or importer of the hazardous chemical, physical, chemical and toxicological data as per the criteria given in the relevant schedule of the Manufacture, Storage and Import of Hazardous Chemicals Rules, 1989.

- Each drum/tank marked as “Dangerous”

Acetaldehyde: https://www.services.bis.gov.in/tmp/WCCHD34619900_20062022_1.pdf

Storage

- Stainless steel storage tanks are recommended, preferably equipped with cooling coils through which refrigerated brine may be circulated. The storage temperature should be maintained below 20 degree Celsius

- If stored without refrigeration, a pressure tank is required. The pressure to be maintained by a blanket of nitrogen.Acetaldehyde, particularly under pressure, should be kept away from contact with air to prevent the formation of highly explosive peroxides

- Avoid use of copper or copper alloys in tanks, lines, or fittings. There is a possibility of formation of explosive copper compounds.

Handling

- The low boiling point of the liquid makes it difficult to handle without considerable vapour losses. To minimize this, a closed system should be used. Not to apply air pressure to transfer acetaldehyde. Provision for emergency venting should be made.

- Acetaldehyde drums should be opened only after thorough cooling below 20 degrees Celsius

- Labelling stipulations have been kept the same for both substances.

The codes stipulate annual medical examination for each employee engaged production and handling of acetone and acetaldehyde to determine levels of exposures if any.

India consulting on draft codes of safety for acetone, acetaldehyde

India consulting on draft codes of safety for acetone, acetaldehyde