On October 31, 2025, the State Administration for Market Regulation of China promulgated the mandatory national standard “Safety Technical Code for Work in Confined Spaces” (GB 46768-2025). The standard will take effect on May 1, 2026.

This standard integrates and updates previous standards, including the recommended industry standard issued in 2012, “Code for Prevention of Occupational Hazards in Confined Space Operations.” It specifies safety management requirements for work in confined spaces, as well as technical safety requirements before, during, and after such work, and explains corresponding verification methods. The standard applies to work in confined spaces and its safety management.

Scope of Application

The standard stipulates safety management requirements for confined space operations and technical safety requirements before, during, and after such work, along with verification methods. It applies to confined space operations and their safety management.

However, it does not apply to confined space operations and safety management in enterprises engaged in the production and handling (including storage) of hazardous chemicals, chemical and pharmaceutical industries, or confined spaces on ships.

Definition of Terms

Confined spaces: Spaces that are fully or partially enclosed, not designed as fixed workplaces, accessible for personnel entry and work, and prone to accumulation of toxic or harmful substances, flammable or explosive gases, or oxygen deficiency.

Requirements for Enterprises

- Management Ledger: Enterprises with confined spaces must identify such spaces, establish a confined space management ledger, and update it in a timely manner.

- General Provisions: The enterprise’s safety management system must clearly define responsibilities of confined space work approvers, work supervisors, monitors, and workers; include safety training for confined space operations; work approval procedures; safety protection measures; emergency rescue equipment and facility management; and operating rules.

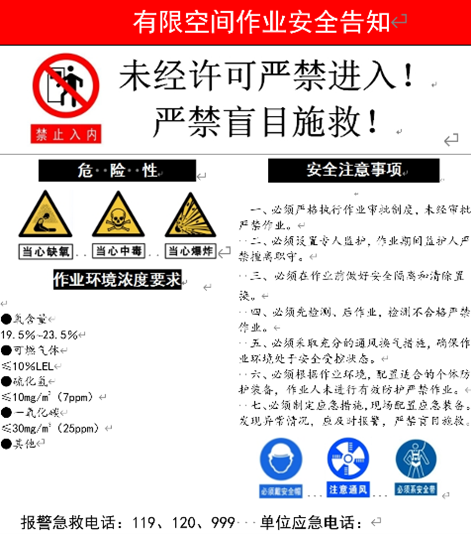

- Confined Work Area and Safety Warnings: Prominent locations at confined space work areas and their entrances must display a “Confined Space Work Safety Risk Board.” Below is an example of the display format provided in Annex B of the standard:

Confined Space Work Safety Risk Board

- Work Environment Assessment: Confined space work may proceed only if initial inspection and measurement results meet all of the following conditions:

- Oxygen content: 19.5% VOL to 23.5% VOL

- Concentration of flammable gases: ≤10% of the Lower Explosive Limit (LEL)

- Concentration of toxic or harmful gases: ≤ maximum allowable concentration or short-term exposure limit specified in GBZ 2.1 “Occupational Exposure Limits for Hazardous Factors in the Workplace – Part 1: Chemical Hazardous Factors.” If no such limits exist, use the time-weighted average permissible concentration.

The overview of the standard can be accessed at the following URL (Simplified Chinese). As of November 2025, full-text access from Japan is not available:

https://openstd.samr.gov.cn/bzgk/std/newGbInfo?hcno=C26BA1B610497F860D280ACF929D3F7D

China Issues Mandatory National Standard “Safety Technical Code for Work in Confined Spaces”

China Issues Mandatory National Standard “Safety Technical Code for Work in Confined Spaces”