Guidelines for the Installation & Maintenance of Continuous Emission Monitoring Systems (CEMS) for Industrial Premises/Facilities Version 7.0 were released in Malaysia on June 21, 2019. The Guidelines are a document that stipulates the details of Continuous Emission Monitoring required for industrial premises/facilities under the Environmental Quality (Clean Air) Regulations 2014. The Guidelines specifically address the following items.

-

- CEMS equipment and the pollutants that are continuously monitored

- The industrial sectors (activities) that are subjected to the CEMS requirements under the Environmental Quality (Clean Air) Regulations 2014

- Requirements in application of installing CEMS

- Requirements on Quality Assurance Plan and reporting requirement

The Guidelines are a 90-page document, consisting of six chapters and the following appendices.

Appendix 1 Registration form for CEMS related service providers

Appendix 2 Application form for the installation of CEMS for the industrial sectors

Appendix 3 Functional test audit report format

Appendix 4 Calibration & variability test/annual surveillance test report format

The original text of the Guidelines can be downloaded from the following URL.

https://www.doe.gov.my/portalv1/wp-content/uploads/2013/01/GUIDELINE-FOR-THE-INSTALLATION-MAINTENANCE-OF-CEMS-FOR-INDUSTRIAL-PREMISES-OR-FACILITIES-VERSION-7.0-JUNE-2019.pdf

CEMS installation procedure

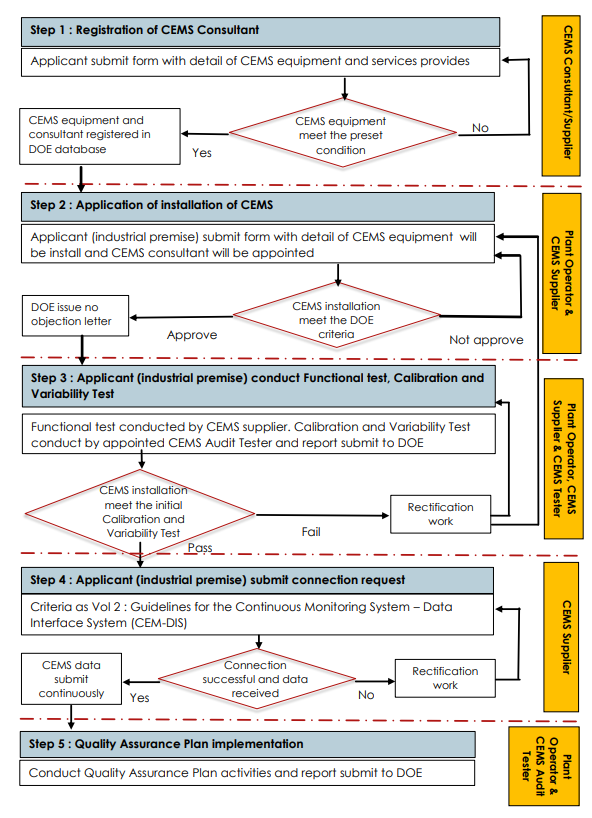

The figure below (Figure 2.1 of the Guidelines) summarizes the entire procedure required to install CEMS. Plant operators shall refer to the CEMS equipment and consultants registered with the Department of Environment Malaysia (DOE), select the appropriate one, and apply the detailed information to the DOE. After that, the functional test of CEMS (calibration and variability) shall be conducted. If there are no problems with the test results, the data shall be connected to the DOE server to check the status of the transmission of the data measured by the CEMS. Finally, a Quality Assurance Plan (QAP) that stipulates the maintenance and performance evaluation of the CEMS shall be prepared and approved by the DOE.

Malaysia releases guidelines on continuous emission monitoring systems (CEMS) for factory exhaust gas

Malaysia releases guidelines on continuous emission monitoring systems (CEMS) for factory exhaust gas