The Evolution of Sustainable Industry and the ESG Imperative

The management of industrial land in Thailand has reached a defining moment, shifting from traditional productivity models to a holistic sustainability framework. As the primary governing body for the nation’s industrial zones, the Industrial Estate Authority of Thailand (IEAT) has served as a cornerstone of economic development for more than five decades, facilitating the transition from an agrarian society to a manufacturing powerhouse.Tthe modern era, however, demands a more sophisticated approach.

This movement traces back to the “Eco-Industrial Estate” (Eco I.E.) program. IEAT was the first organization in Thailand to adopt sustainable industrial development principles, launching the DEE + Net Project (Development of Eco Industrial Estate & Networks) in collaboration with the German Technical Cooperation (GTZ). The initiative began with five pilot sites: Map Ta Phut, Bang Pu, Northern Region, Eastern Seaboard, and Amata City Chonburi. By 2010, this vision matured into the “Eco-Industrial Town” concept, emphasizing a balance among economic growth, social equity, and environmental stewardship. This institutional evolution is now aligning with the United Nations Sustainable Development Goals (SDGs). Adopted by all UN Member States in 2015, the 17 SDGs serve as a universal call to action to end poverty and protect the planet by 2030. In Thailand, this alignment is further accelerated by the global Environmental, Social, and Governance (ESG) trend. International investment decisions increasingly rely on ESG criteria, and Thai exporters face significant external pressures, such as the European Union’s Carbon Border Adjustment Mechanism (CBAM). To remain competitive, Thai industry must pivot toward low-carbon production to support the national targets of carbon neutrality by 2050 and net zero emissions by 2065.

The SDGs I.E. Standard: Criteria, Execution, and Certification

The “SDGs I.E.” standard represents the maturation of IEAT’s agenda, moving beyond qualitative goals toward a rigorous, indicator-based system. The standard is executed through the IEAT RAPID policy, which focuses on five pillars: revenue creation (green utilities), accessibility for stakeholders, professionalism (ISO standards), innovation (BCG model), and digital transformation.

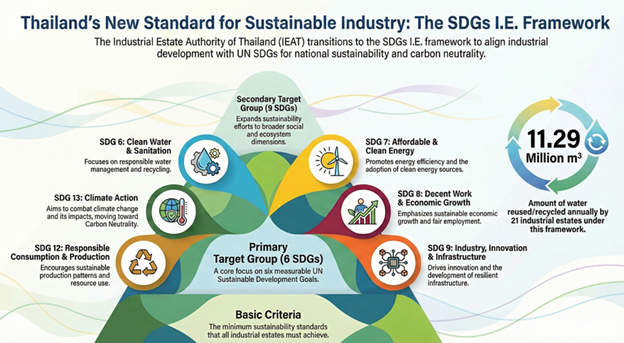

The SDGs I.E. framework divides the 17 SDGs into three distinct categories to ensure efficient resource allocation:

1.Baseline Standards:

These foundational requirements include basic environmental compliance, safety regulations, and adoption of ISO 14001.

2. Core Group (6 SDGs):

These represent areas where industrial activities have the most significant impact:

- SDG 6 (Clean Water): Water reuse and recycling

- SDG 7 (Clean Energy): Renewable energy, such as solar rooftops

- SDG 8 (Decent Work): International safety and labor standards

- SDG 9 (Innovation): “Smart 4.0” infrastructure

- SDG 12 (Responsible Production): Resource efficiency via the circular economy

- SDG 13 (Climate Action): Greenhouse gas (GHG) accounting and reduction

3. Secondary Group (9 SDGs):

These address broader dimensions, such as gender equality (SDG 5) and quality education (SDG 4), to create a total sustainability ecosystem that extends “beyond the factory walls.”

A summary figure illustratesthe SDGs I.E. certification framework.

Execution and Timeline

IEAT is implementing the program in stages, with the goal of transitioning all 67 industrial estates nationwide to the SDGs I.E. standard by 2032. In the near term, IEAT’s roadmap for 2025-2026 roadmap focuses on “Green & Digital” initiatives, including a 3,400-million-baht pilot project with the World Bank to install floating solar farms in Map Ta Phut and Laem Chabang.

Certification and Leadership

IEAT utilizes a five-level certification hierarchy:

- Level 1: Eco-Engagement

- Level 2: Eco-Encourage

- Level 3: Eco-Champion

- Level 4: Eco-Excellence

- Level 5: Eco-World Class.

The SCG Chemical (SCGC) RIL Industrial Estate currently stands as the leading example, having achieved “Eco-World Class” (Level 5) status for seven consecutive years. Other recognized participants include Map Ta Phut Olefins, Thai Polyethylene, and Thai MMA, which have been commended for providing critical data to support the eco-industrial movement.

Future Outlook and Recommendations

The future of the SDGs I.E. program is closely linked to the Bio-Circular-Green (BCG) economic model. Upcoming developments include the full commercial operation of Smart Parks—combustion-free zones powered entirely by renewable energy and 5G/IoT networks. IEAT also plans to launch a carbon credit exchange and establish green supply chains that can be quantitatively measured to meet global trade requirements.

Factories that align with these standards stand to gain several advantages as followed:

- Cost Reduction: Improved energy and water efficiency (Eco-efficiency) lowers operational costs.

- Financial Incentives: Access to green finance with lower interest rates and tax exemptions; some estates offer “two-year land rent-free” promotions for early adopters.

- Global Competitiveness: Compliance with CBAM and other international environmental regulations ensures continued access to European and American markets.

- Enhanced Image: IEAT certification serves as a “social license to operate,” building trust with surrounding communities and attracting ESG-conscious investors.

For those working within these estates, proactive adaptation is essential. Recommended actions include:

- Rethink and Redesign: Shift from linear consumption to a circular model; consider how waste from one process can serve as raw material for another.

- Start Measuring Now: Begin rigorous GHG accounting and product carbon footprint assessments; don’t wait for legal mandates—early reporting is a critical first step.

- Integrate Digital Tools: Adopt IoT and AI for real-time monitoring of energy and resource usage to minimize losses.

- Leverage Technical Support: Engage with IEAT “ISB Coaches” and consultants to conduct feasibility studies and internal audits.

The transition to a sustainable industrial estate resembles a natural coral reef: while individual factories function as distinct organisms, their survival depends on a shared, healthy environment in which one entity’s output becomes another’s input, creating a resilient ecosystem capable of withstanding the rising tides of global change.

Transforming Thailand’s Industrial Landscape: From Eco-Towns to the SDGs I.E. Paradigm

Transforming Thailand’s Industrial Landscape: From Eco-Towns to the SDGs I.E. Paradigm