Thailand’s industrial landscape is undergoing a substantial regulatory transformation aimed at enhancing environmental governance through digitalization. The shift from the manual, paper-based systems of the past two decades to the fully integrated electronic frameworks introduced this year represents a significant change. This article outlines these developments, emphasizing the historical context of environmental personnel, the three new notifications issued by the Department of Industrial Works (DIW) in B.E. 2569 (2026), and a strategic perspective for factory operators in Thailand.

The Foundation of Industrial Environmental Personnel in Thailand

To understand the current legal landscape, one must begin with the Ministry of Industry Notification on the Determination of Types and Sizes of Factories, Methods for Controlling Waste, Pollution, or Anything Affecting the Environment B.E. 2554 (2011).

What Are Environmental Personnel?

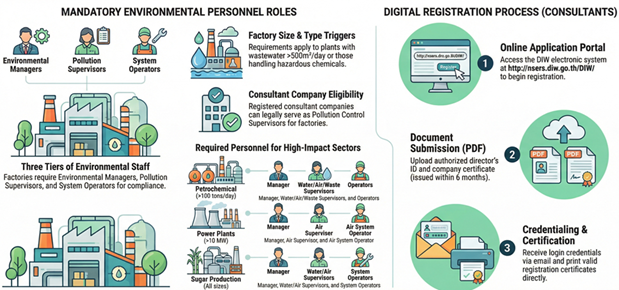

Under these regulations, “Environmental Personnel” are individuals responsible for overseeing and operating pollution prevention systems within a factory. They fall into three distinct roles:

- Environmental Managers: Oversee environmental administration, pollution prevention at the source, and emergency action plans.

- Pollution Treatment System Controllers: Individuals or consulting firms registered to monitor, control, and maintain treatment systems for water, air, or industrial waste.

- System Operators: Staff stationed at pollution prevention system machinery to ensure continuous and efficient operation.

Which Factories Require These Personnel?

Factories with higher pollution potential must appoint environmental personnel. Examples include:

- Wastewater: Factories with influent BOD > 100 kg/day, wastewater > 500 m³/day, or those using heavy metals such as zinc, cadmium, or c

- Air Pollution: Sugar mills (all sizes), power plants (≥ 10 MW), petroleum refineries, and cement plants.

- Waste Management Focus: Petrochemical plants, pulp and paper mills, and involved in the sorting or landfilling of hazardous waste.

Duties and Benefits

The primary duty of these personnel is to ensure that the factory’s discharge of pollutants—whether into the water, air, or as solid waste—remains strictly within legal standards. Controllers must analyze pollutant levels and report the results to the DIW. Operators must remain at their posts whenever the systems are running to prevent malfunctions.

The benefits of this system are twofold. For the state, it establishes a decentralized monitoring network that makes factories accountable for their own emissions. For the factory owners, it reduces the risk of legal penalties, helps prevent environmental incidents that could lead to closure, and supports positive relations with the surrounding communities.

Related Historical Laws

Before the 2026 revisions, the system relied on several key DIW notifications, including:

- DIW Notification B.E. 2554 on qualifications, training, and standard exams for environmental personnel.

- DIW Notification B.E. 2556 on the notification and receipt of notification (the process of informing the DIW of appointed staff).

- DIW Notification (No. 2) B.E. 2564, which introduced early electronic registration for consulting firms.

Overall Picture of the DIW Environmental Personnel System

The 2026 Regulatory Update — A Step Toward the Digital Era

In B.E. 2569 (2026), DIW issued three new notifications to modernize the entire lifecycle of environmental personnel management. These laws shift the process from a mix of paper and digital to a fully electronic environment.

The Three New Notifications

- DIW Notification Re: Qualifications, Training, and Standard Exams for Environmental Personnel (No. 2) B.E. 2569:

Amends the 2011 (B.E. 2554) version to allow all training and examination processes to be conducted electronically. - DIW Notification Re: Registration as Water, Air, or Industrial Waste Pollution Controllers B.E. 2569:

Replaces previous registration rules and requires all registrations for individuals and consulting firms to be completed through the DIW’s computer network. - DIW Notification Re: Notification and Receipt of Notification of Environmental Personnel (No. 2) B.E. 2569:

Changes how factories inform the DIW about their appointed staff by converting the “Receipt of Notification” into a digital “e-Certificate” format.

Key Changes and Improvements

The most significant change is the removal of physical paperwork. Under the new laws, an “Electronic Certificate” (e-Certificate) now carries the same legal weight as a physical one. The system also enforces the limit of five factories per controller, applied automatically through the digital database.

Table: Comparison Between Previous and New Regulations (B.E. 2569)

| Feature | Previous Regulations (B.E. 2554/2556/2564) |

New Regulations (B.E. 2569) |

|---|---|---|

| Submission Method | Paper forms or partial online submission. | Mandatory Electronic Systems via the DIW computer network. |

| Proof of Registration | Physical “Notification Receipt” or paper certificate. | Electronic Certificate (e-Certificate). |

| Renewal Process | Manual filing within 90 days before expiry. | Automated Electronic Renewal via the client system 90 days prior. |

| Personnel Changes | Notification by mail or in person within 15–30 days. | Real-time digital updates via the DIW network. |

| Monitoring Cap | Controllers limited to 5 factories (difficult to verify manually). | System-enforced cap; the digital system rejects a 6th factory automatically. |

| Consultant Registry | Mix of digital and paper processes. | Fully digital registration for individuals and consulting companies. |

Predicted Impacts and Strategic Proposals for Factory Owners

Predicted Outcomes of the New Laws:

The transition to a fully digital system will likely have the following impacts:

- Increased Transparency:

The DIW will have a “real-time” view of every environmental professional in the country. This makes it impossible for a controller to “ghost” sign for more than five factories, a practice that sometimes occurred under manual systems. - Operational Efficiency:

Factories will no longer need to travel to the DIW or the provincial industrial offices to submit paper forms such as the old Appendix 1 and 2. - Enhanced Compliance Tracking:

The system will likely send automated alerts when a staff member’s three-year registration is nearing expiration, reducing the risk of accidental non-compliance.

Strategic Recommendations:

The following adaptation strategy should be implemented:

- Audit and Digitalize Personnel Records:

The new law requires high-quality digital uploads (likely PDFs) of credentials, such as ID cards and training certificates. Each environmental staff member (Manager, Controller, and Operator) should have their documents scanned and stored securely to expedite electronic notification. - Synchronize Internal Calendars with the 90-Day Renewal Window:

Renewal must occur within 90 days before expiration. A centralized compliance calendar should trigger an internal alert 120 days before any certificate expires, allowing 30 days for staff to complete required e-training before the 90-day DIW window opens. - Verify “Controller Capacity” for Third-Party Consultants:

Factories using consulting firms must be proactive. Since the system automatically blocks any controller already managing five factories, consultants should provide a DIW-issued “Digital Capacity Report” before contract signing to ensure the factory can be correctly linked in the database. - Invest in Digital Literacy for Administrative Teams:

Because the “Receipt of Notification” is now an e-Certificate, administrative or HR teams must be trained on the DIW platform. Factories should designate a “Digital Compliance Officer” to manage electronic submissions and ensure no personnel appear “expired” in the DIW system.

Conclusion

The B.E. 2569 (2026) notifications represent more than formatting change; they reflect the DIW’s commitment to improving environmental protection regulations. By removing paper-based processes, the state makes compliance easier while reducing opportunities to bypass the law. For proactive factory owners, this digital shift reduces administrative overhead and provides clear, real-time proof of their commitment to a cleaner, safer Thailand.

DIW has published the regulations, which can be downloaded via the QR code in the image above.

DIW has published the regulations, which can be downloaded via the QR code in the image above.

Thailand, Update on DIW Regulations on Environmental Personnel System

Thailand, Update on DIW Regulations on Environmental Personnel System