Overview of the key components and structure of the PPRS

On April 2, 2020, PCX Solutions released the first version of the Plastic Pollution Reduction Standard (PPRS), a framework designed for the registration and issuance of plastic credits for projects focused on recovering and diverting post-consumer plastic wastes. The PPRS is developed in the Philippines, one of the countries in the world experiencing the worsening plastic crisis. PCX Solutions continuously and constantly reviews and updates the PPRS and holds public consultations to garner feedback and comments from various stakeholders and the general public. The latest version was published on June 5, 2024, which is the eighth version. The eighth version will be discussed in this report.

The PPRS currently contains 5 modules, namely:

- Module 1: Definition of Terms and Scope

- Module 2: Objectives, Principles, and Safeguards

- Module 3: Project Registration

- Module 4: Plastic Crediting Process

- Module 5: Plastic Credit Related Claims

The scope of the PPRS

The following list is the qualified post-consumer plastic materials defined in the PPRS:

- Materials made of the 7 types of plastics and other plastics (O):

- Polyethylene Terephthalate (PETE or PET)

- High-Density Polyethylene (HDPE)

- Polyvinyl Chloride (PVC)

- Low-Density Polyethylene (LDPE)

- Linear Low-Density Polyethylene (LLDPE)

- Polypropylene (PP)

- Polystyrene or Expanded Polystyrene (PS or EPS)

- Any synthetic or natural organic materials group, including resins, resinoids, polymers, cellulose derivatives, casein materials, and proteins including, among others, acrylic or poly methyl methacrylate, acrylonitrile butadiene styrene (ABS), polyamide (nylon), polycarbonate and polylactic acid

- Composite materials containing the plastics and material types listed above, such as multilayer paper boards with polyethylene and/or aluminum layers.

Multi-component materials, like tires and UBC (used beverage cartons), are grouped under “Used Tires Credits” and “UBC Credits,” respectively. Plastic and synthetic components in used tires cannot be mechanically separated in end-of-waste processing facilities, resulting in it having its own credits group. The PPRS follows a 1:1 conversion of “Used Tires Credits” to plastic credits.

An important information to note is that PPRS Plastic Credits can only be issued for the collection and processing of post-consumer plastic waste. Plastic waste from industrial, manufacturing, or pre-consumer sources does not qualify for credit generation. However, there are exclusions, such as production rejects, recalls, and scraps. PPRS follows the “Guidance on Waste Definitions” by the Circular Plastics Alliance to distinguish between post-consumer wastes and pre-consumer/post-industrial wastes.

Core objectives and principles of the PPRS

The PPRS’ core objective is to establish a credible and verifiable framework for plastic credit programs. PCX Solutions collaborates with partners to ensure a secure, transparent system for collecting, transporting, and processing plastic waste to prevent environmental leakage. Through an audited process, the weight of processed post-consumer plastic waste is converted into plastic credits, which are tracked in the PPRS Registry. These credits can be purchased by individuals or organizations to take responsibility for plastic waste and contribute to reducing plastic pollution.

Moreover, the PPRS is guided by the following principles:

| Items | Details |

|---|---|

| Conservativeness | All claims must be accurate, validated, and verifiable. When uncertainties arise, organizations agree to adopt a more cautious approach and disclose the methodologies supporting their claims. |

| Integrity and Consistency | PCX Solutions works with third-party VVBs to ensure consistent and accurate application of the PPRS across users and Project Partners. These bodies consistently assess projects to verify all data and information and confirm the accuracy of reported impacts. A third-party audit is required before issuing, selling, or retiring plastic credits. |

| Transparency and Traceability | PCX Solutions will provide relevant and sufficient stakeholder information to the public, ensuring it is easily accessible, timely, and practical. Plastic Credit Certifications and Project Registrations issued by PCX Solutions will include comprehensive and verified documentation and evidence. |

| Additionality | PCX Solutions focuses its efforts in communities with significant plastic waste mismanagement. In January 2021, the World Wide Fund for Nature (WWF) defined additionality as an activity that takes place specifically because of the crediting mechanism and would not have happened otherwise. To ensure claimed benefits for plastic credits are truly additional, projects must establish a baseline that reflects the regional status quo. This baseline, assessed by VVBs, should use public, published sources, preferably localized data. Any environmental or socio-economic improvements beyond the baseline qualify the project for the PPRS, even without higher plastic collection volumes. Socio-economic benefits must also be validated by the VVB. Baselines are reviewed every five years or when updated public data becomes available for reassessment. |

| Policy Interactions | The PPRS aligns with policies like Extended Producer Responsibility (EPR). If national policies on plastic credits differ from the PPRS, users must adhere to the stricter standard. Unlike some EPR policies, the PPRS emphasizes additionality. |

| Continuous Improvement | PCX Solutions is dedicated to continuously improving the PPRS to benefit the environment and stakeholders. It ensures alignment with international best practices by benchmarking processes and results. Feedback from PPRS users is welcomed, reviewed, and incorporated into the standard when appropriate, following the amendment process. |

What is the project registration process in the PPRS?

Below is the summary of the criteria and requirements for projects to be eligible for plastic credits issuance:

- Criteria 1: Sound Environmental Process

To generate plastic credits, it is crucial that all collected plastic waste is diverted from the environment and processed through a well-managed facility. The repurposing of post-consumer plastic should not result in any negative environmental effects.- Requirement 1.1: The Project Partner must supply documented evidence detailing their project’s scope, processes, and technologies, such as process flow diagrams, evidence for the use of calibrated equipment, etc.

- Requirement 1.2: The Project Partner must provide documented proof of their identification, evaluation, monitoring, and adherence to national or local environmental regulations.

- Requirement 1.3: The Project Partner must provide documented evidence of the assessment of relevant environmental risks and impacts, along with the preventive or mitigation measures in place.

- Criteria 2: Additionality and Ownership

The PPRS outlines two types of additionality—quantitative (tonnage) and qualitative (environmental and socio-economic)—to guide the determination of additionality. Either one of these two additionality types needs to be demonstrated by the Project Partner and validated by the VVB.- Requirement 2.1a: Quantitative Additionality arises from increased sourcing or processing of post-consumer plastic waste, as well as the financial support needed to maintain the project’s operations. The project must not operate below the regional baseline, and only the volumes collected or processed above the baseline are eligible for plastic credits.

- Requirement 2.1b: Qualitative Additionality and Environmental/Socio-Economic Benefits is demonstrated by the Project Partner by showing that their project improves upon the regional baseline. Even if no additional waste volume is collected or processed, the project can still qualify as additional if it demonstrates improvements to the baseline conditions, such as increased wages of workers, inclusion and empowerment of vulnerable groups (e.g., indigenous people, etc.), increased livelihood opportunities, etc.

- Requirement 2.2: Ownership of Credits – Only tonnages that have not been previously claimed by any individual or organization, and have no unresolved disputes or uncertainties regarding ownership, are eligible for plastic credit issuance.

- Criteria 3: Safeguards Systems

Project Partners must show that their operations do not negatively affect the environment and society. If unavoidable adverse effects occur, measures must be in place to prevent, mitigate, and reduce these impacts.- Requirement 3.1: Due Diligence – VVBs will perform due diligence activities, such as stakeholder consultations, Environmental and Social Impact Assessment, and onsite validation, to confirm the implementation of the project’s safeguards.

- Criteria 4: Traceability and Transparency

- Requirement 4.1: Documented Information – The Project Partner’s adherence to the PPRS must be supported by documented evidence. All necessary documentation required by the PPRS should be accessible to the VVB and, if requested, to PCX Solutions.

- Requirement 4.2: Mass Balance and Chain of Custody – Any discrepancies in the chain of custody must be analyzed and explained by the Project Partner. Supporting documents for all transactions must be available to the VVB and PCX Solutions and may include:

- Monitoring records and evaluations

- Collection records

- Processing records

- Inventory records

- Discrepancy reports and analysis

- Communication of plastic credit transactions with other partners, if applicable

- Impact monitoring and reporting

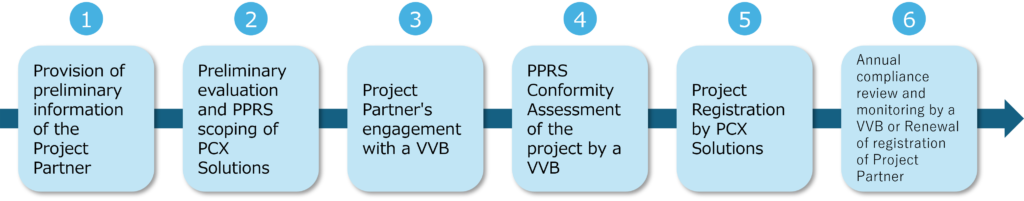

The figure below outlines the project registration process in the PPRS. The PPRS registration is valid for 5 years from the date of the Project Registration. Additionally, PCX Solutions has a grievance mechanism for any stakeholder or member of the public to provide feedback or file a grievance regarding any project that is currently registered under the PPRS at any time.

Figure 1. Project Registration process in the PPRS

Figure 1. Project Registration process in the PPRS

How are plastic credits issued in the PPRS?

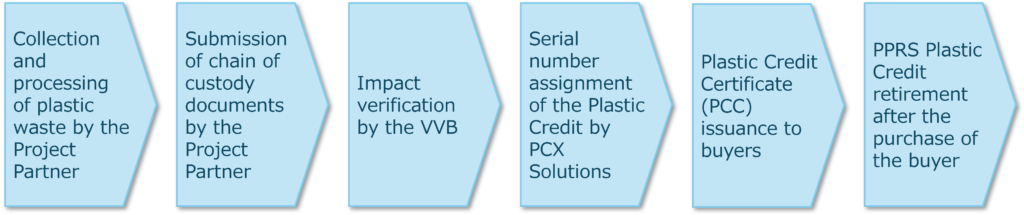

The figure below demonstrates the process for plastic credit issuance in the PPRS:

Figure 2 Plastic credit issuance flow

Figure 2 Plastic credit issuance flow

Analysis of the PPRS and plastic credits

PPRS is aligned with international frameworks and standards, such as the UN SDGs, The International Finance Corporation’s Performance Standards on Environmental and Social Sustainability, The Asian Development Bank’s Safeguard Policy Statement, and The World Bank Environmental and Social Framework, which shows its credibility and relevance. Furthermore, the usage of PPRS has no geographical restrictions. Currently, there are PPRS-registered projects in about 7 countries.

Moreover, PPRS ensures the assessment by a third-party VVB and highlights additionality, which are both important to demonstrate that registered post-consumer plastic collection and processing projects are truly contributing to the diversion of plastic wastes in the environment.

Plastic credits are tools to promote investment in post-consumer plastic waste facilities which ultimately is the key to the reduction of unmanaged and mismanaged plastic waste in the environment. The plastic credits help entities take responsibility and provide action to mitigate the plastic pollution crisis. By assigning a financial value to plastic waste, plastic credits create an economic incentive to process plastic waste, including low-value plastics that are typically ignored. Plastic credits play a significant role in mitigating plastic pollution, transitioning to a circular economy, and achieving long-term environmental sustainability.

Philippines, Summary and Analysis of the Plastic Pollution Reduction Standard (PPRS)

Philippines, Summary and Analysis of the Plastic Pollution Reduction Standard (PPRS)